Handling Robot

Integrating robots into pick-and-drop applications becomes popular and standardized day by day. The effectiveness of robotic arms has become more apparent in recent years. Automation helps to standardize and stabilize product quality and production processes. Improve factory production productivity, save time and cost on each product.

The movement and arrangement of products and equipment in the factory seems simple, but it takes a lot of time and human effort. But with robots, it becomes simple and effective, meeting the variety of objects to be picked up such as size, material, and weight.

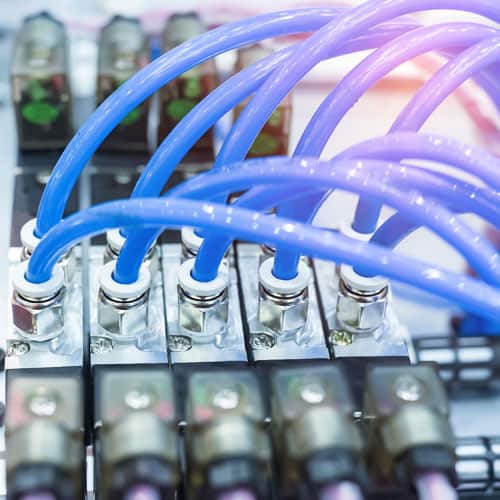

The handing robot system is integrated at the same time with surrounding devices such as conveyors, grips, and slides to help the robot become flexible and diverse. Along with that are advanced technologies such as image processing applications, conveyor monitoring to help improve accuracy, processing ability as well as system productivity.

Some practical applications:

- Pick and place

- Material handling

- Stacking

- De-stacking

- Packaging

RobotNext with a team of engineers who have gone through various large and small projects in the application of gripping robots has full capacity and experience as well as product and application understanding. We are confident to meet the needs of the factory in the most efficient way

Products & System

The equipment needed for machine tending robot systems

Gripper

Conveyor

Pneumatic Devices

Advanced technology solutions and software

Vision Technology

Conveyor Tracking