6 CRUCIAL ELEMENTS OF A PNEUMATIC SYSTEM

In many industrial applications, including air-powered tools, robot end-of-arm tooling, automated equipment, and motion control systems, pneumatic systems employ pressurized air to create motion. Because they are a reliable, efficient, and secure way to provide movement and control, pneumatics are widely employed in industry and production. Pneumatic systems need to have the right parts, though, in order to function as best they can. Here, we concentrate on the six components that are necessary for a pneumatic system to operate as intended.

The 6 most important pneumatic system

Although pneumatic systems depend on many other parts, these six are essential for supplying control and movement in industrial settings:

Air compressor

To extract and compress air from the surrounding environment, pneumatic systems rely on air compressors. In order to subsequently be utilized as the force that generates movement in the equipment it provides, the air pressure increases as its volume decreases. To make sure the intake air is dry and clean, it is filtered twice: once before it goes into the compressor and once again before it goes into the pneumatic system.

Air reservoir

The cleaned compressed air is kept in this air reservoir until it is required. The main reason they are an essential component of most industrial pneumatic systems is that the compressed air flow needed to run them is seldom consistent. A buffer between the compressor and plant activities is provided by a reservoir with a controlled output flow. Pneumatically driven tools and equipment will operate consistently when appropriately designed, resulting in less wear and tear on the compressor controls and stable plant pressure under variable flow circumstances. Put differently, the reservoir acts as a holding area for prepared compressed air, making it available for distribution right away and capable of triggering equipment very instantly.

Filter-Regulator-Lubricator, or FRL At the moment of use, compressed air is treated by the FRL. Particulate matter, moisture, and occasionally hazardous vapor are eliminated via filtering. To ensure correct and reliable functioning, the regulator should be set below the minimum plant pressure and at the pressure advised by the maker of the tool or machine. In some high cycle rate applications, it is advised to use a lubricator to lightly lubricate the compressed air, since this can extend the life of control valves and actuators. Lastly, to satisfy safety regulations, a shut-off isolation valve is frequently attached to the FRL.

Pneumatic valves

The quantity and direction of airflow to the machinery or equipment are controlled and regulated by valves in a pneumatic system. They are necessary for the efficient management and operation of pneumatic systems.

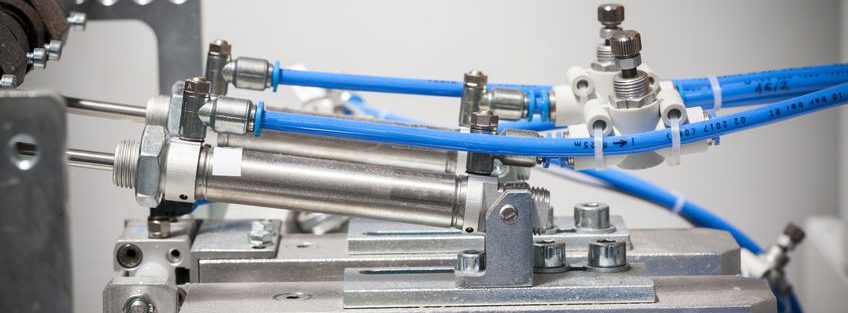

Pneumatic circuit

For safe and efficient operation, pneumatic systems, like electronic systems, need a circuit that is appropriately constructed. However, pipes, tubing, and fittings are used in pneumatic circuits instead of wires and connections to transfer compressed air to the various parts of the system. For many years to come, a well-designed pneumatic system will operate consistently and without issue.

Pneumatic cylinders/actuators

Although they come in a wide range of forms and arrangements, pneumatic cylinders are a frequently utilized type of pneumatic actuator. All varieties generate either rotational or linear motion using the force provided by compressed air.

The Pneumatic System’s Advantages

Pneumatic systems are a standard in the majority of industrial and manufacturing facilities due to their simplicity. The following are the main advantages of pneumatics in various applications:

Cost-effectiveness

The cost of the system is generally lowered since pneumatic components are generally cheap. Furthermore, the system and its components never need expensive or time-consuming maintenance procedures since they are robust and easy to use.

Dependable and adaptable performance

Pneumatic systems have a straightforward design and dependable, straightforward components, which make them ideal for usage in the high-temperature, corrosive, and unclean conditions typically encountered in industrial buildings. Pneumatic valves may also be utilized in a wide range of applications across the facility since they make it simple to regulate and manage pressure and airflow.

Both ecologically benign and safe

Pneumatic systems may be used safely and worry-free in hazardous regions where there is usually a risk of fire or explosion since they use compressed air, not electricity, to create motion in industrial instruments and equipment. Furthermore, air may be returned to the atmosphere after usage without needing to be cleaned or treated further.

If you are interested in Pneumatic System and automation or want to know more about how to improve production efficiency, please contact Robotnext today for advice and cost support. Details via hotline: 0909 914 837.

Other reference robot accessories: