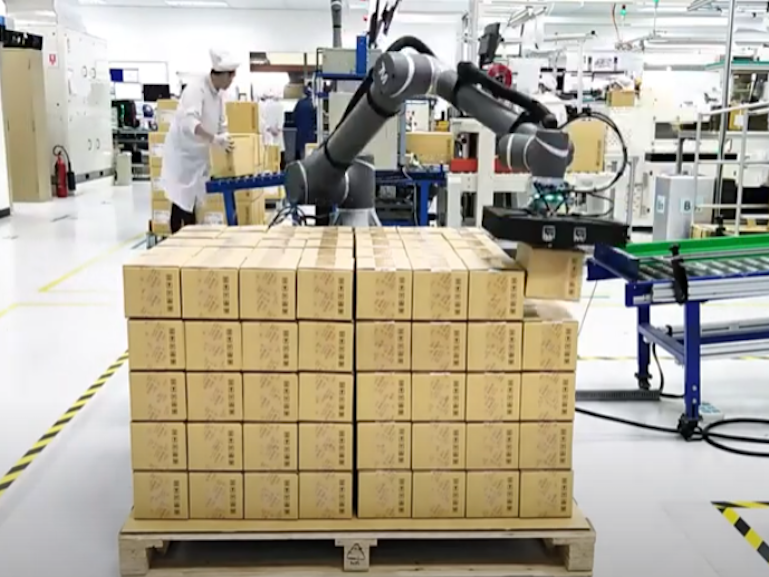

The Next Wave: Industry 5.0 promotes human centric automation

The objective of human centric automation, which refers to the close integration of human labor with automation technology, is to deliver additional value-added services that motivate firms to become more robust, flexible, and efficient. 1. What is the majority of manufacturers? The majority of manufacturers are now aware of Industry…